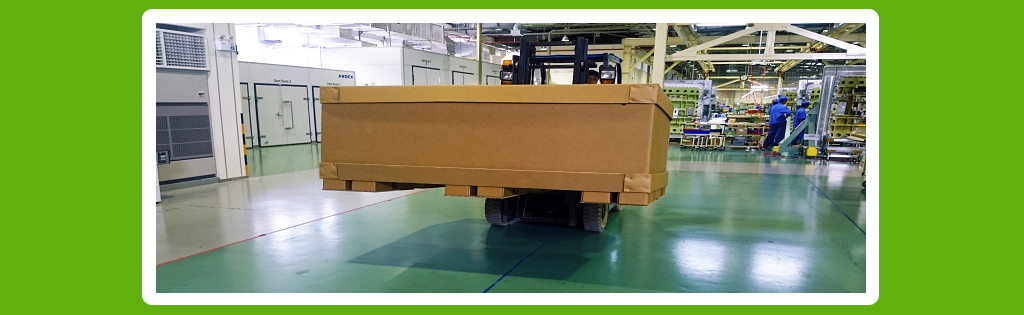

Heavy, Large, Long and Important products can be stacked in container

To reduce total logistics costs

1. Pack more into containers .

2. Decrease package dimensions and weight.

3. Decrease Damaged Goods.

4. Reduce packaging and secondary materials.

5. Reduce inventory of packing materials.

6. Simplify packing and unpacking operations.

7. Design packaging according to the conditions of the destination country.

Download brochureTri-Wall solves these challenges in export packaging.

Reduce transportation costs by stacking in containers

Stacking allows more products to be placed in a container, reducing transportation costs.

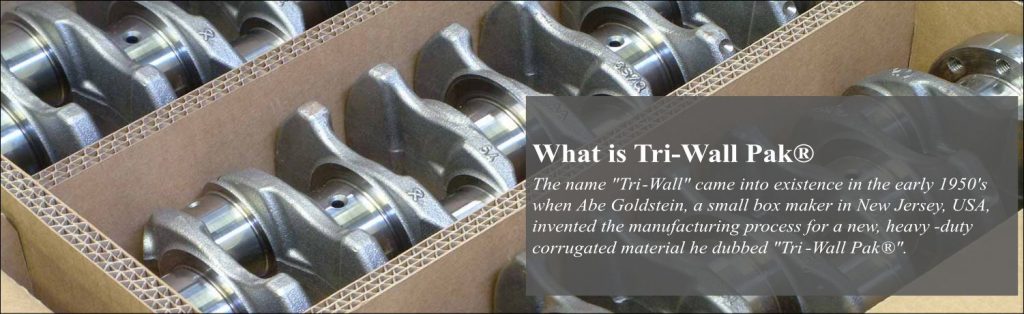

Protects products from water and moisture

It maintains its strength and protects important products even in the hot and humid environment of a container ship for a long time.

Safe and easy packaging operation

Since secondary materials can also be reduced, workers and secondary material costs can be reduced.

Effective use of warehouse and factory space

Delivered in compact collapsed form.

Recyclable and Reusable

Unpacking is easy, disposal is easy after arrival, and there is no cost for this process

Reduce environmental impact

By replacing wooden boxes with TRI-WALL PACK, about 60% of wood resources can be saved, packaging materials are lightweight and small, and CO2 emissions can be reduced because they can be transported in large quantities at once by stacking

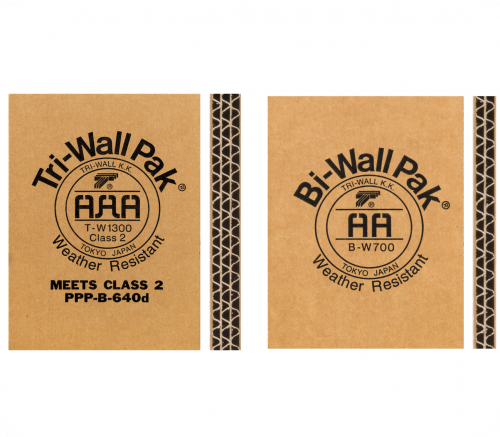

Tri-Wall meets many global transport packaging standards. It has been used for 70 years around the world in a variety of industries to improve logistics efficiency.

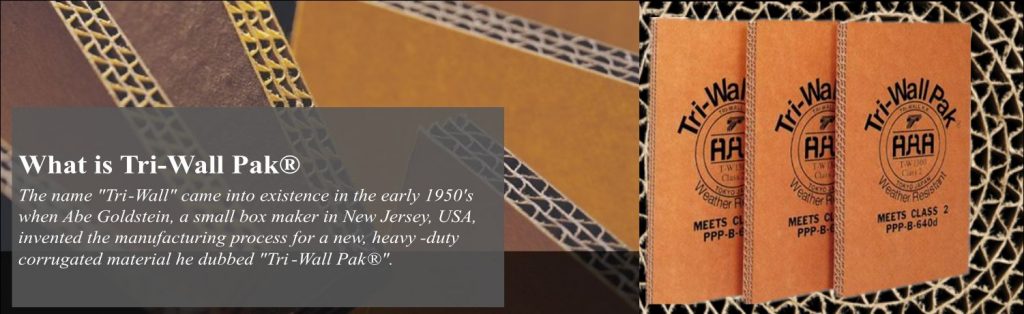

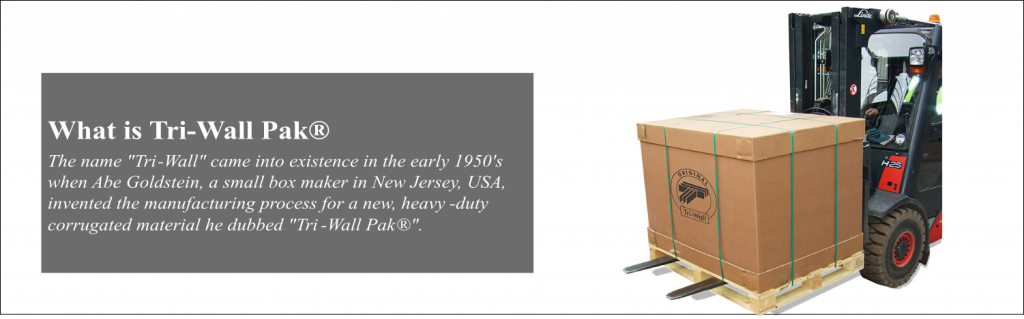

Tri-Wall was developed in 1952 by two brothers at Abe Goldstein, a small box manufacturer in New Jersey, USA.

As an alternative to wood and metal packaging, Tri-Wall’s advantages were quickly recognized; within a decade, Tri-Wall could be found in virtually every area of industrial and agricultural transportation packaging.

It conforms to government and transportation packaging standards in more than 42 countries around the world. Its quality is proven by standards around the world, such as the most stringent former US Federal Standard PPP-B-640d, US Rail Transport Standard Rule 41, US Rail Transport Standard Item 222, NATO standards, IATA (International Air Transport Agreement) standards, and British and German government standards.

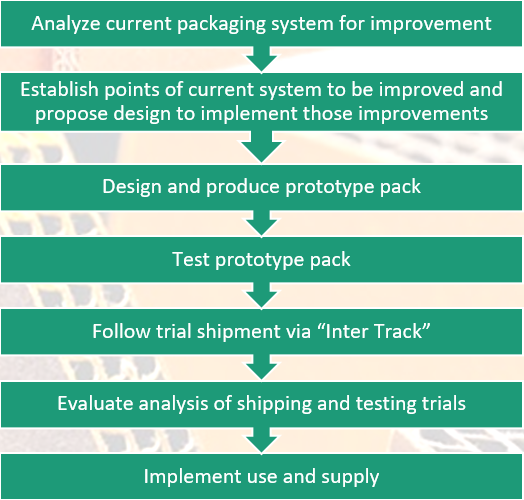

We offer tailor-made packaging to suit your products.

Frequently asked questions from people who are worried about introducing Tri-Wall

What is the MOQ?

Since it was developed in the United States in the 1950s, it has evolved with the idea of “one box, anywhere in the world”. We can make even one piece in Vietnam.

To provide flexible support to customers anywhere in the world, we have established more than 120 factories in over 20 countries around the world, making us the only global packaging company in the world.

One World, One Tri-Wall – Delivering products and services that set the standard for quality, reliability and excellence wherever our customers are.

Is Tri-Wall expensive?

“Innovation” is the basis of Tri-Wall’s activities.

Our proposals to our customers start with design. Most of the packaging we propose is custom-designed to meet specific requests that match our customers’ products and manufacturing capabilities, with the ultimate goal of “total cost reduction” for our customers.

If you look at the packaging material alone, it is more expensive than ordinary cardboard boxes, but it is not necessary to use Tri-Wall for everything.

We use Tri-Wall where strength is required and combine it with other packaging materials such as ordinary cardboard boxes or other packaging materials for other parts to create an appropriate design.

Can you make a sample and test it?

Yes, If you approve the design and quotation, we can create samples and perform tests. Tri-Wall Vina has a pressure testing machine and other tests method can be done by cooperating companies.

Despite the rise in labor costs, raw materials, fuel and other factors, exports will continue to grow in Vietnam.

That’s why you should start using Tri-Wall now

During the pandemic, container transportation costs have risen sharply. It has now settled down and we hope that such a situation will not happen again. We have learned that transportation costs for trucks and ships and exchange rates can change rapidly, so we think it is necessary to use container space more efficiently than ever before.

I think there are many places in Vietnam where business expansion has led to a shortage of factory space.

If you are worried about strength and are using wooden boxes, you may find cases where valuable factory space is being used up by inventory of packaging materials. With Tri-Wall, it can be delivered folded, so it doesn’t take up much warehouse space.

Why not start packing with Tri-Wall at this opportunity?

We want to continue to be an essential presence for our customers through our services that enable them to say “I can’t do without Tri-Wall” by providing packaging design tailored to the nature of the product and the situation in the receiving country, reducing total logistics costs, reducing CO2 emissions through environmental contributions, and other plus alpha services.